The growing hemp market is growing. After all, hemp parts, fibers, seeds, and flowers are a lucrative business for hemp companies all over the country. Among these parts, hemp biomass is particularly valuable. If you are unfamiliar with this term and want to know what it is and its uses, this guide will tell you all about it.

Key Takeaways

- Hemp biomass is the organic material left behind after the flowers and other parts of the hemp plant have been harvested.

- There are two types of hemp biomass: hemp fiber biomass, which includes the stalks and leaves, and CBD biomass, which is harvested from the hemp flower for CBD production.

- The harvesting process for hemp biomass involves drying the trims and leftovers for 3-5 days. This biomass typically contains around 10% CBD, although indoor-grown hemp crops can produce up to 15% CBD.

- Hemp biomass is versatile and can be used to make CBD extracts and oils, teas, fuels, paper and packaging materials, and fibers.

- The demand for hemp biomass has seen growers focus on CBD-rich hemp biomass, due to its profitability.

What is Hemp Biomass?

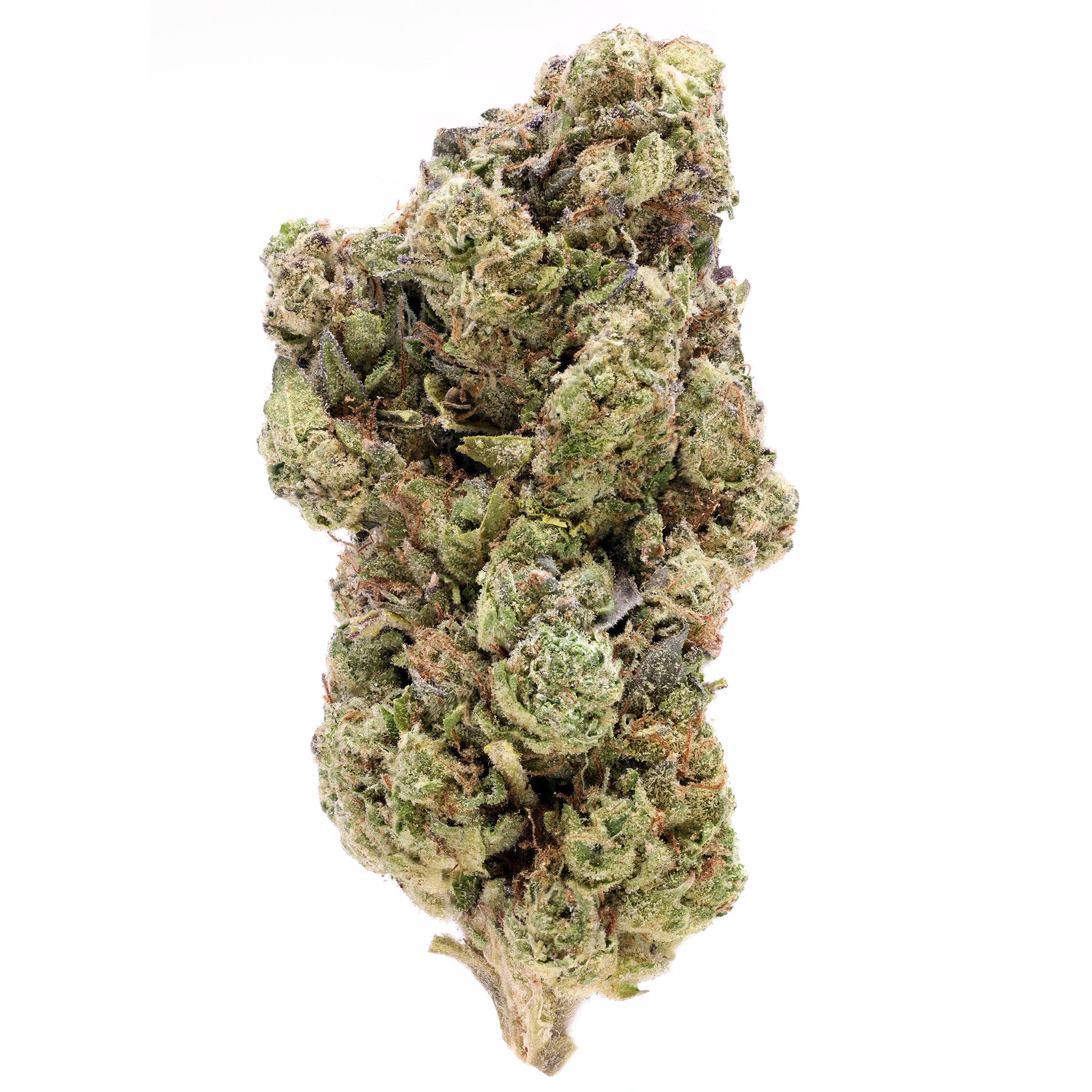

Hemp biomass is the collection of the organic material that remains after the flowers and other parts of the plant have been harvested. Even though biomass is often considered waste in farming, researchers have found that hemp biomass (stalks and leaves) can be used to create eco-friendly, compostable, and durable products.

Before continuing, it is important to note that there are two types of hemp biomass: hemp fiber biomass (hemp remains) and CBD biomass. The latter is used for CBD production, being directly harvested from hemp flower.

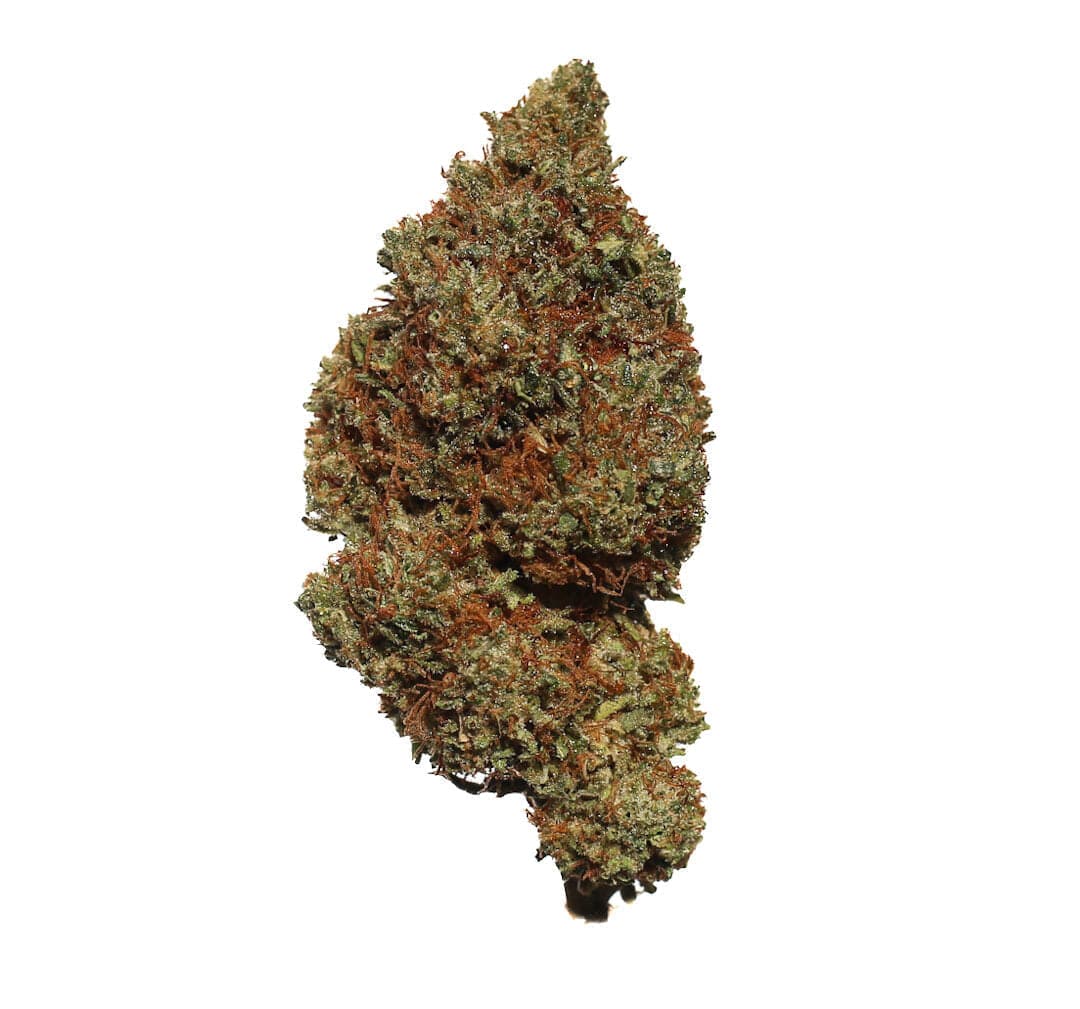

Farmers focus on producing premium CBD biomass to sell. When CBD-rich hemp buds are hand trimmed, like our Botany Farms’ craft CBD flower, some leaves called “sweet leaf” are left behind to ensure there are no excess materials in the final product, which ensures a better smoking experience. However, these leaves also have good levels of CBD that become part of the biomass.

How is Hemp Biomass Harvested?

To produce high-quality biomass, the trims and leftovers are left to dry in a lab facility or an open-air barn. Here, moisture stops being as important as it was in the growth process of the plant since humidity reduces the quality of hemp biomass. If moisture is retained, mold will grow and pose a potential threat to the harvest.

Hanging the stalks builds up mold near the center, so each branch is separated and hanged individually. This way, the drying process is quicker and generates less product loss. The drying phase can take 3-5 days, and some farmers use a clip fan to accelerate this process.

Once completely dry, the stalks and leaves are shredded to make them smaller. They are then packed and ready for sale. This blend contains around 10% CBD, which is a standard amount of CBD in biomass. Some farmers, especially those who grow their hemp crops indoors, produce up to 15% CBD in their biomass.

If hemp biomass is intended to create fibers, the transformation process is way different. Usually, the biomass undergoes a retting process to separate the fiber from the rest of the stalk. This process takes 2-4 weeks to have the fiber ready to be transformed into different products, but its profits are great since many industries are starting to use hemp fibers for textile purposes.

Nowadays, producing hemp biomass outdoors can yield up to 500–1,500 pounds per acre. These calculations can vary depending on the agricultural practices employed by growers. It is common to find higher, better-quality yields of hemp biomass in indoor-grown hemp plants since they are controlled to deliver the best results.

What is Hemp Biomass Used for?

If it is rich in CBD, hemp biomass will be used to produce CBD extracts and oils. If the methods of extraction are of high quality, the resulting product will have at least 30–70% potency. It is important for companies to buy hemp biomass that has been indoor-grown because it contains fewer contaminants than outdoor-grown hemp plants.

This way, CBD isolates developed from such biomass will be pure and deliver better effects. Besides CBD extracts, hemp biomass is used to produce many other items, such as:

- Teas: The leaves are removed from the stalk once dry and can be used to make tea. Whether they are used loose or put into tea filter bags, the taste and aroma of hemp tea is certainly something to try out.

- Fuels: Due to the current climate crisis, bioenergy is emerging as the new alternative to fossil fuels. Thanks to hemp's adaptability to soils and reconstruction of them, researchers believe that it could become the next high-energy crop because it does not require a lot of water and has a high biomass yield. However, due to the little research done on the possible properties of this plant for energy purposes, the use of hemp for bioenergy is limited.

- Paper and packaging materials: The core of the hemp plant's stalk is rich in cellulose. Hemp is known for having very strong fibers, which makes it an ideal crop to produce hemp paper and packaging materials. Additionally, it can also be used to create bioplastics.

- Fiber: Probably one of the most known uses of hemp biomass, hemp fiber has been produced for centuries to make ropes, fabrics, and insulation. Hemp fiber is water- and rot-resistant and can be two times stronger than wood. As a plus, it is completely biodegradable.

As you can see, hemp biomass can be used for a wide variety of purposes. For this reason, many farmers have switched to the harvesting of biomass to obtain bigger profits, especially from CBD-rich hemp biomass.

A downside to this sudden increment in hemp biomass production is the lack of high-end biomass. The vast majority of farmers cultivate hemp outdoors, which increases the probability of contaminated crops and the use of pesticides. Hence, the best hemp biomass found on the market usually comes from indoor-grown crops, which are completely controlled and regulated to achieve a high-quality product.

Check out the video for more information on hemp biomass and ways to utilize spent cannabis and hemp biomass.