Live resin is arguably one of the most popular concentrates in today's market. Fans will tell you that it yields a fantastic flavor, while detractors will swear it doesn't.

For us, it is one of the best products we can find to taste all the goodness of the cannabis flowers, and it has captured the imaginations of consumers and producers alike.

The process, however, isn’t as simple as with other cannabis extractions. In this article, we want to walk you through how live resin is made. Read on to learn some cannabis science and how to make live resin.

New to live resin? Check out our favorite products.

Key Takeaways

-

Live resin is made using fresh-frozen cannabis material using solvents like ethanol, butane, propane, or CO2.

Live resin is a frozen, wax-like substance and is known for its high potency, often being stronger than traditional cannabis concentrates.

The closed-loop extraction system is used to preserve cannabinoids, terpenes, and flavonoids, ensuring a flavorful experience.

Live resin can be transformed into various products like edibles, tinctures, and vape cartridges.

What is Live Resin?

The name “live resin” denotes that this product is made from fresh cannabis. You might wonder why anyone would want to use fresh cannabis instead of dried products—after all, isn’t that the common bud we all love and smoke?

Some strains contain more cannabinoids than others, so they can actually be stronger than their dried counterparts if harvested at just the right time during their maturation period.

Also, several compounds called terpenes found in fresh flowers give cannabis its distinctive tastes and smells (like citrus or pine), but these are mostly lost when cannabis is dried out.

This is the part where live resin comes into play. It is a marijuana concentrate that looks like frozen and hardened wax. It's made by squeezing fresh cannabis material through a filter to remove the plant matter.

What remains is a thick, oil-like substance that is sticky enough to set into a chunk. It is the most potent form of marijuana and can be up to 10 times stronger than traditional cannabis concentrates.

What's Live Resin Weed?

Live Resin Weed is a cannabis concentrate that has emerged in the last couple of years. The process for creating live resin weed involves extracting cannabinoids from the plant material using a solvent such as ethanol or butane, then purging the solvent from the extract in an oven until only the terpenes remain.

The resulting product is similar to shatter or rosin, but its unique extraction method often has a more refined flavor and aroma than traditional concentrates.

Live resin weed is typically made using trim (the leaves and stems) instead of buds, usually reserved for other concentrate forms such as CO2 oil and rosin. Because live resin weed is made with a trim instead of buds, it tends to be less expensive than other concentrates on the market.

Another advantage of live resin weed is that you can consume it without additional processing or cooking. When added to joints or pipes, it melts into a liquid form that can be absorbed directly into your body through your lungs or mouth.

Also, learn whether you can smoke live resin and the best live resin strains.

Live Resin Process

Freeze the Biomass (Plant matter)

The most important part of learning how to make live resin is freezing your plant matter before extracting it. If you don't do this, then the solvent won't be able to strip off all of the trichomes, and even worse, it could potentially ruin your material!

During extraction, you get better results if you freeze your herb first, because freshly frozen material releases its terpenes better when exposed to heat or pressure, depending on the method you're using.

Live Resin Extraction Process

After freezing, the buds are put in a solvent like butane, propane, or CO2 and extracted to produce a high-quality oil.

This method is different from other extraction methods because it doesn't use heat. Many extraction methods use heat to extract cannabinoids from plant matter, but this can destroy the terpenes in your cannabis.

Solvent Blend

The first step in live resin extraction is to choose your solvent blend. This combination of solvents will dissolve cannabinoids, terpenes, and other plant material into an oil-like substance known as hash oil or rosin. The most common solvent blends include ethanol, butane, propane, and CO2.

Ethanol: Ethanol is the most commonly used solvent used in live resin extraction because it dissolves many different compounds in cannabis, including THC, CBD, and other terpenes.

Ethanol can be made with grain alcohol (with an extremely low boiling point) or with sugar water via fermentation. The alcohol content of ethanol usually ranges between 60% and 90%.

Those who just want to learn how to make live resin for experimental purposes might find ethanol the easiest way to create a DIY product that is safe for consumption.

Butane: Butane is another commonly used solvent for live resin extraction because it’s easy to find and affordable. However, butane is highly flammable, so you must handle it with care during this process.

It also evaporates quickly, which means you only have a short window of time to use it before it evaporates completely out of your mixture. Butane has been known to cause explosions when not handled carefully, so you must follow all safety measures.

Propane: Propane is another solvent commonly used for live resin extraction because it’s easy to find and affordable. It also evaporates quickly, so you don’t waste time waiting for your mixture to dry before smoking or vaporizing it.

However, propane does not dissolve plant material and other solvents, so you will need more propane than other solvents while still getting similar results in potency and purity.

CO2: Carbon dioxide (CO2) is one of the most popular live resin extraction methods because it works great with cannabis strains with higher amounts of THCV, which can be difficult for other people's solvents to break down properly into oil form without losing potency.

CO2 is heavier than air gas, so it doesn't evaporate like butane or propane. Instead, CO2 is pressurized and used as an extraction solvent that helps pull out the cannabinoids from your plant material without causing any damage to them.

This method also benefits from extracting more terpenes than distillation methods because CO2 doesn't burn off these compounds as other solvents do.

Chilling Solvent

Once the resin has been heated and strained, it is time to chill the solvent. The resin is encased in a glass container and placed in a freezer for 20 minutes, allowing the solvent to cool down without burning or causing damage to the product.

Closed-Loop Extraction

Live resin is extracted using the closed-loop extraction process. This ensures that all cannabinoids, terpenes, and flavonoids are preserved in the final product. The closed-loop system used in live resin extraction involves an industrial vacuum oven. This pulls out the solvent while keeping the temperature low enough to preserve all of the taste and flavor of your precious cannabis flowers.

This process preserves all of the terpenes and flavonoids found in your strains, which means you'll get a much more flavorful experience than with other extracts.

Post Processing

Post-processing live resin refers to the processes performed after the extraction process is complete. These include things like drying, curing, trimming, and packaging.

Residual Solvent Purge

The final step is to purge the live resin of any remaining residual solvents. This is done by running the material through a vacuum oven and using a nitrogen flush to remove any traces of residual solvent.

This is an important step because residual solvents can pose health risks when inhaled or ingested, so it's essential to remove them from your product before you consume it.

Make Your Products

Now that you have your live resin, you can turn it into any product. You can make edibles, tinctures, vape carts, and more.

Use your live resin in a recipe or add it to an existing one for edibles. This will give you the best potency and flavor possible. For example, if you're making an apple pie, add some live resin to the apples before baking them. This will infuse the flavor into your pie and make it taste amazing!

To make tinctures, simply add your live resin to a glass jar filled with alcohol (vodka works well). Shake it up for about 10 minutes, and then let it sit for 24 hours, or until all the alcohol has evaporated from the mixture. The result is a thick, oily substance that can be taken orally as medicine or used topically to manage skin conditions such as acne or psoriasis.

Where to Buy Live Resin

If you’re looking for the best places to buy live resin online, you’ve come to the right place! At Botany Farms, we produce some of the finest-quality cannabis products. Our live resin is made from fresh-frozen flowers extracted using CO2. After extraction, the concentrate is filtered and cleaned before consumption.

Our live resin is extracted from top-quality genetics grown organically in our state-of-the-art facility. The plants are grown under natural sunlight and with proper nutrients. This ensures that they are free from pesticides and other harmful substances that can put your health at risk. Our products are tested by third-party labs to guarantee potency and purity.

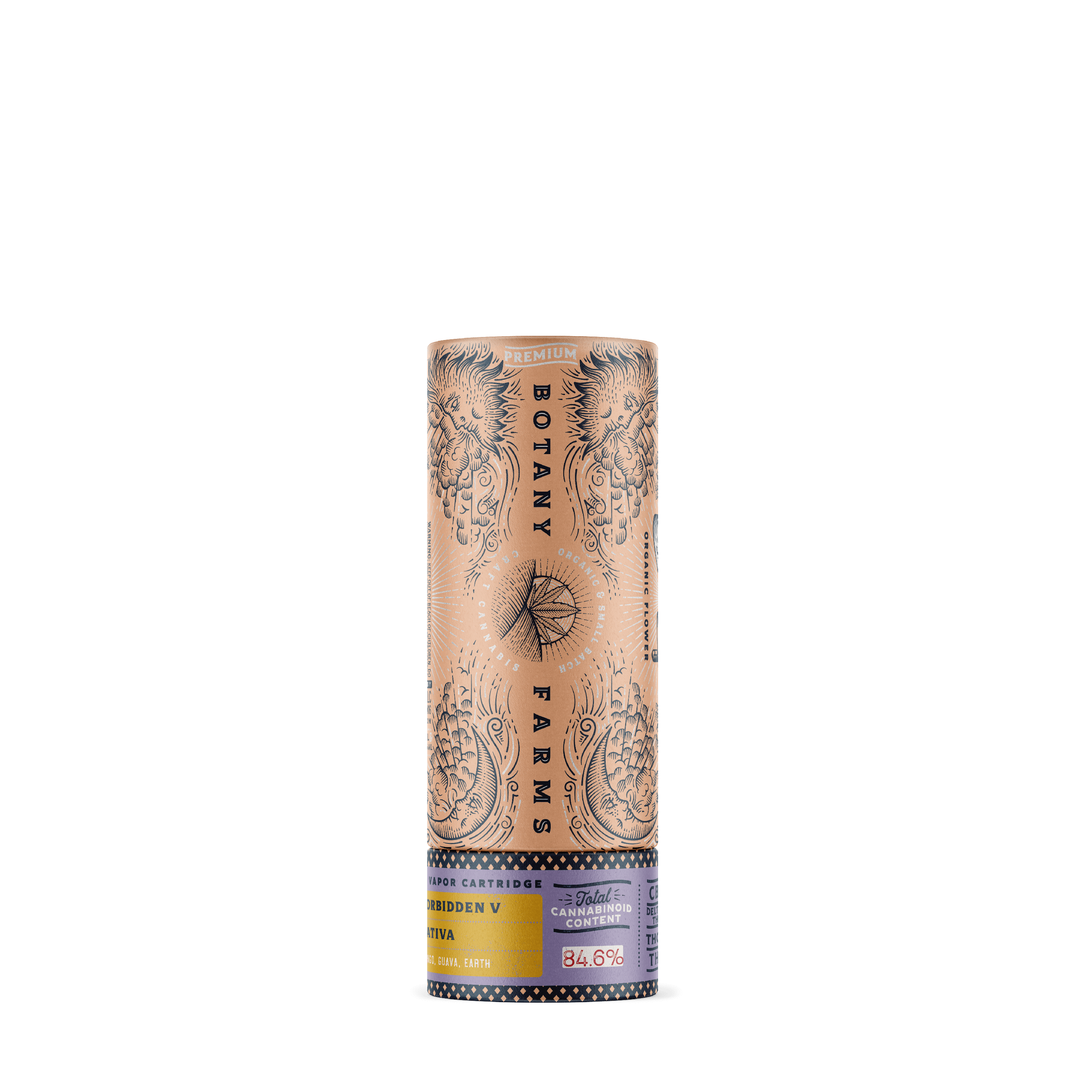

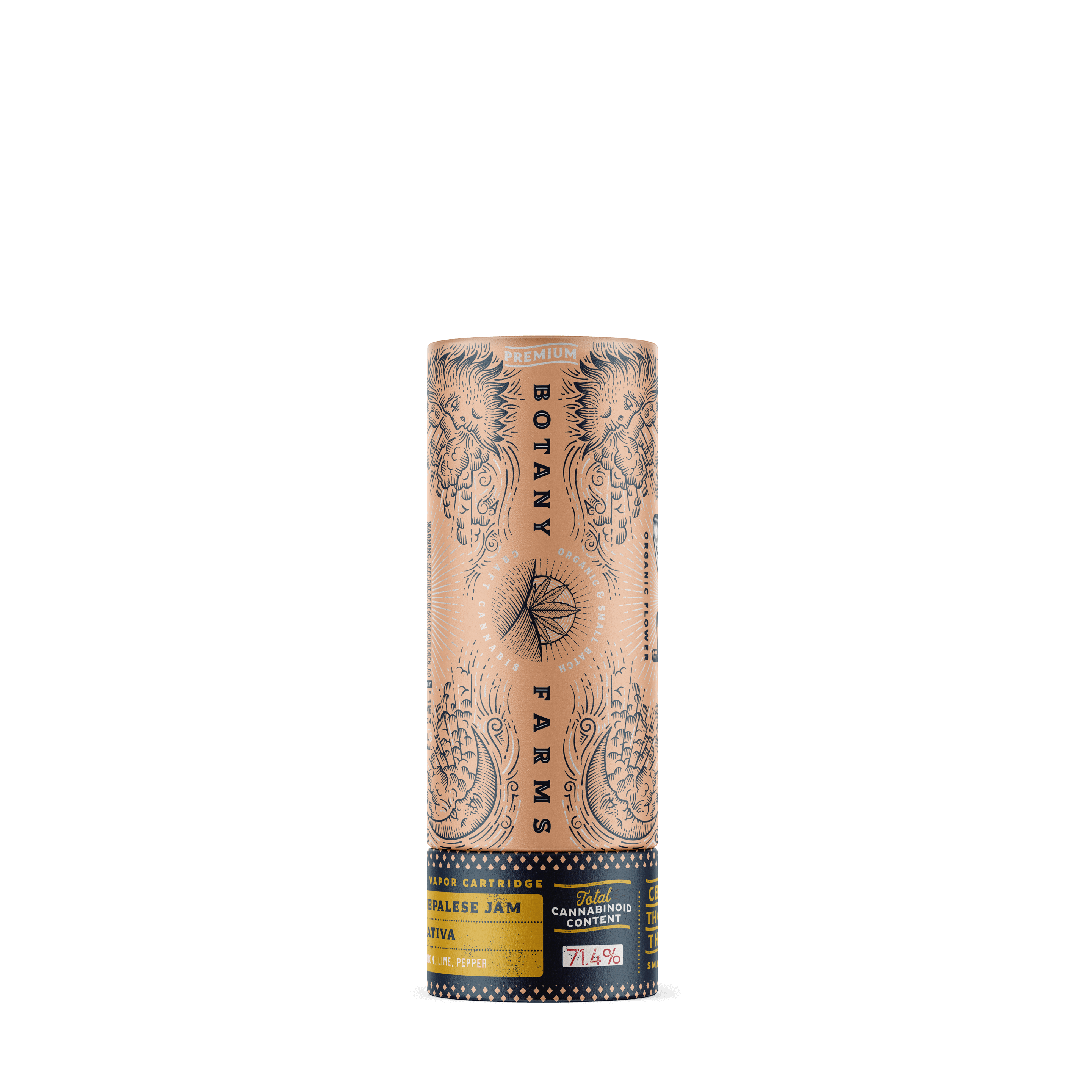

Our fine selection of live resin products include:

Delta 8 Vape Cartridge

Our Delta 8 Live Resin Vape Cartridge is a high-quality, potent and tasty product. The cartridge comes in various terpene profiles, including Sour Diesel, Blue Dream, and Purple Urkle.

This cartridge comprises 100% CO2 extracted cannabis concentrates and contains no PG or PEGs. The oil inside this cartridge has been tested at over 80% THC.

It also contains no artificial colors, flavors, or sweeteners, making it perfect for vaping on the go without any worries of getting caught in public with an odor or taste that could attract attention from others around you!

Live Resin CBD Tincture

Our Live Resin CBD Tinctures are made from the fresh plant material and are extracted using a proprietary process to produce the highest quality product. The full spectrum extract is added to high-grade hemp oil in our tinctures, allowing for the most bio-available delivery method possible.

All our tinctures are made from organic CBD-rich hemp. We never use any pesticides or other chemicals in this process, and we always test for purity and potency, so you know you’re getting the highest quality product available.

Live Resin Delta 8 THC Tincture

Botany Farms' Live Resin Delta 8 Tincture is made from the same high-quality flowers used in the other products in our line. The difference is that we have extracted terpenes from our flowers utilizing a method is known as flash-distillation, or "live resin" extraction.

This results in a pure and potent concentrate that contains all the beneficial cannabinoids and terpenes. This means that you get more than just THC, you get all the effects!

We use CO2 extraction to make our tinctures and edibles. Unlike other companies who use this method, we don't use butane or propane in our process, so there is no residuals leftover. This gives us a higher quality product with no unwanted chemicals or residue.

Botany Farms Live Resin Tincture is perfect for anyone who wants to experience the full range of effects from their favorite strain without having to smoke it or vape it first! It's also great for patients who want to avoid smoking altogether.

Whether you're a cultivator, an extractor, or just a fan who has an interest in how to make live resin—there's something for everyone. And as long as extractors keep innovating with these methods, there will likely be plenty to talk about for years to come.